Our Products

At Thermonik ENG, we specialize in compact electric furnaces (heating furnaces) that leverage our unique high-temperature furnace technology. Our product lineup includes carbon furnaces, multi-atmosphere furnaces, all‑metal furnaces, and chlorination furnaces.

We also provide other types of heating furnaces not listed below. For further details, please refer to the website of Thermonik Inc. (Korea).

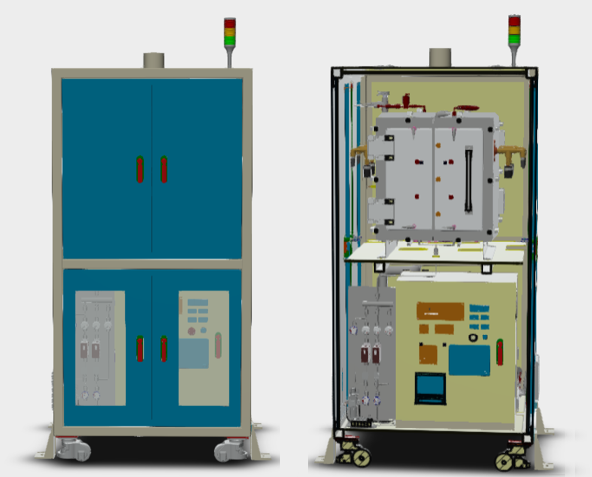

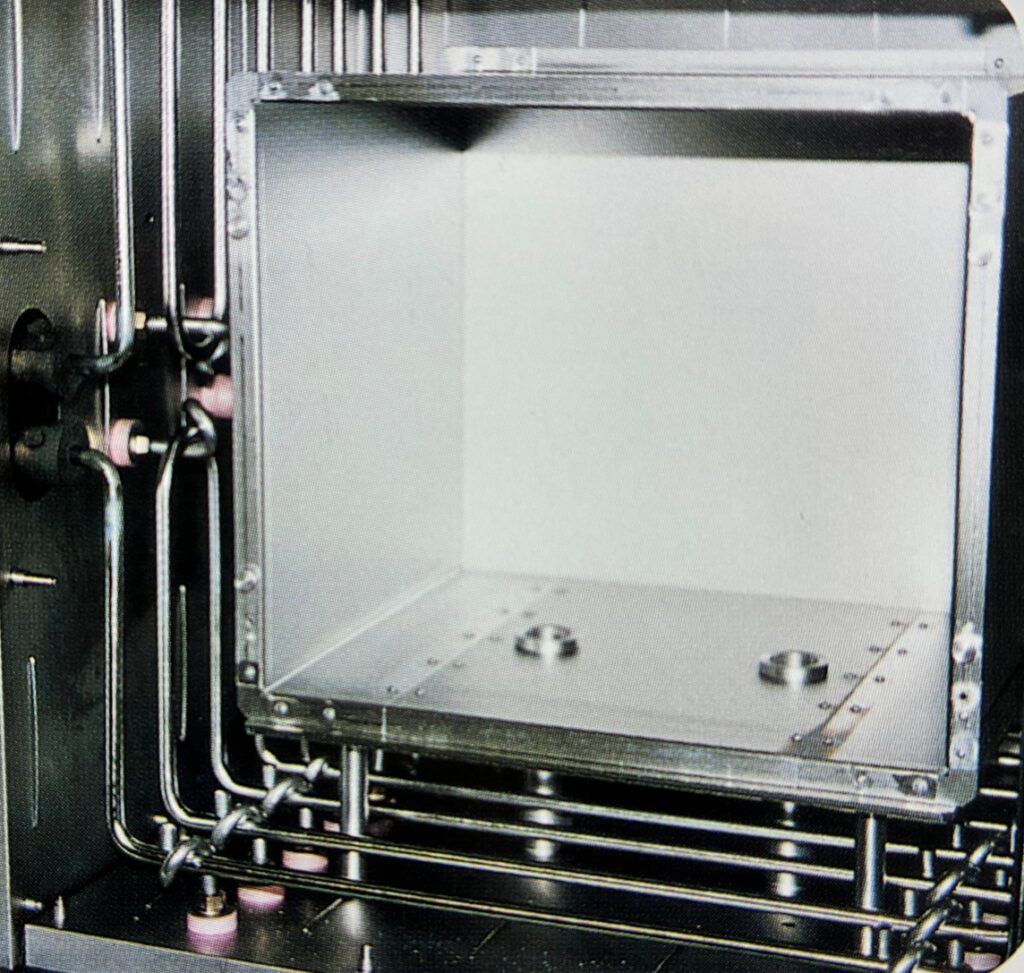

Compact All‑Metal Furnace

What is a Metal Furnace?

An all‑metal furnace is a high-performance heating system in which all internal components—such as heaters, thermal shields/insulation, and chamber walls—are constructed entirely from metals such as tungsten or molybdenum.

This design eliminates the trace contamination that is unavoidable in conventional alumina‑ or carbon‑based furnaces, enabling an ultra-pure, high-temperature, clean processing environment.

It is particularly suitable for ultra-high-temperature processes in vacuum or inert gas atmospheres.

From research and development to mass production, all‑metal furnaces meets the demands of the most stringent temperature and atmosphere control requirements.

How It Works

- Heating Method: Tungsten or molybdenum heaters generate heat, and the metals’ high thermal conductivity helps ensure uniform furnace temperatures.

- Atmosphere Control: To avoid oxidation of metal heaters, the furnace operates in vacuum or in an inert gas atmosphere (e.g., N₂, Ar).

- Clean Design: With no ceramic insulation and an all-metal construction, dust and gas emissions are minimized even in vacuum.

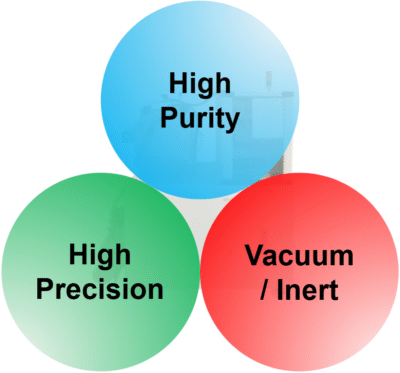

Features (highlights)

The furnace’s all-metal construction minimizes contamination from insulation or other materials.

It can perform high-temperature firing up to 1,800 °C in vacuum or an inert atmosphere (e.g., N₂), allowing materials to be processed while preventing high-temperature oxidation.

- High-Purity Environment

- No contamination from carbon- or alumina-based furnace materials

- Firing without compromising the material’s inherent properties

- High-Precision Temperature Control

- Uniform temperatures within ±a few °C thanks to the high thermal conductivity of metal heaters

- Ultra-High-Temperature Capability

- Stable operation up to 1,800 °C

- Vacuum & Inert Atmosphere Compatibility

- Avoids oxidation and nitriding risks

- Low Outgassing & Low Dust

- Ideal for ultra-clean applications such as semiconductors and optical components

Applications (samples)

- Pre-treatment of conductive materials (e.g., SiC substrates, oxide single crystals)

- Synthesis of high-purity powders (oxides, nitrides, borides)

- Material evaluation requiring precise temperature profiles

- Processes that must avoid furnace degradation from carbon or nitriding

- Sample heat treatment prior to surface analysis

Specifications (excerpt)

| Heating Zone | 140mm×140mm×170mm(D)※ |

| Maximum Temperature | 1,800℃ |

| Vacuum Level | 10-6Pa |

| Atmosphere | Inert atmosphere (e.g., N₂, Ar) |

| Heater | Tungsten rod heater |

| Insulation | Tungsten + Molybdenum |

| Required Utilities | 25 kVA power, cooling water, process gas, air |

Our metal furnace features a compact heating zone and is capable of vacuum and ultra-high-temperature operation, making it particularly suitable for the following applications:

- Research and development applications (rapid evaluation of small samples)

- Test firing during the materials development stage

- Pre-treatment of samples for analysis

- High-purity firing of expensive materials

Keywords

Vacuum, inert gas atmosphere, ultra-high purity, high-temperature firing, contamination prevention, stable temperature control, uniform temperature distribution, precise temperature management, powder material firing, research and development applications

Compact Carbon Furnace

What is a Carbon Furnace?

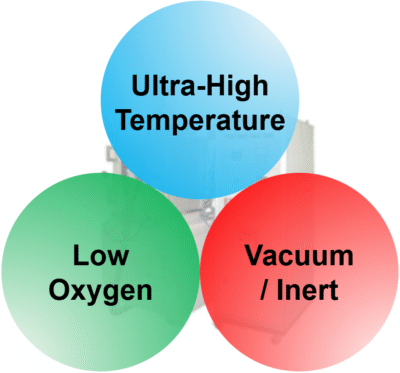

The carbon furnace is an ultra‑high‑temperature heating system in which all internal components—heaters, thermal shields/insulation, and chamber walls—are made of graphite (carbon).

It can achieve temperatures up to 3,000 °C, which are beyond the capability of many conventional electric furnaces, while maintaining an extremely low oxygen concentration inside the furnace.

It is ideal for processes requiring highly crystallized carbon materials or the sintering of ultra-high-melting-point metals, where high temperatures and low oxygen levels are essential.

How It Works

- Heating Method: Electrically powered graphite heaters provide direct heating, raising the entire furnace temperature through radiation and conduction.

- Atmosphere Control: At high temperatures, oxidation is promoted, so the furnace operates in an inert gas atmosphere (e.g., Ar, N₂) to minimize oxygen concentration.

- High-Temperature Design: All internal components are made of high-purity graphite, enabling stable heating up to 3,000 °C.

Features (highlights)

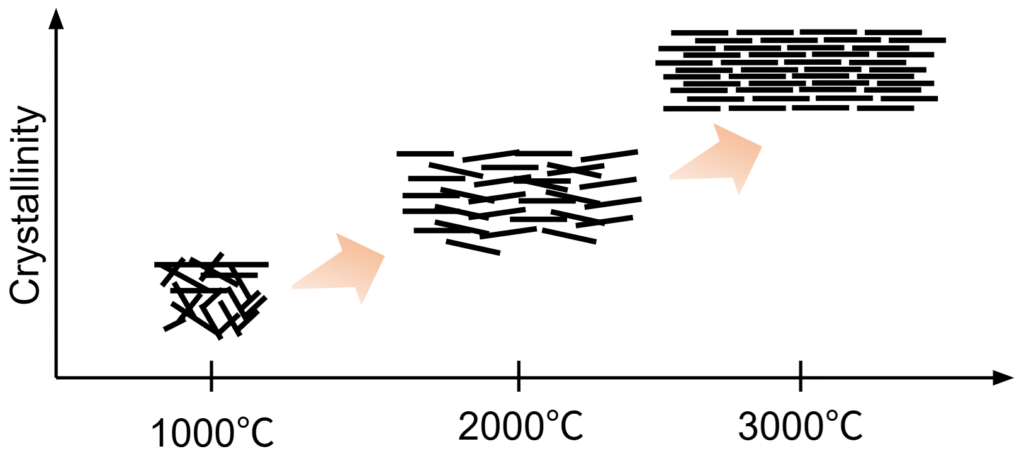

- Ultra-High-Temperature Capability

- Stable operation up to 2,800 °C in normal use and up to 3,000 °C at maximum.

- Low-Oxygen Atmosphere

- With an all-graphite furnace construction, oxygen concentration is minimized, preventing oxidation.

- Ideal for High-Crystallization Processing

- Improves the crystallinity of carbon materials, significantly enhancing lifespan and performance.

- Wide Material Compatibility

- Suitable for compositional testing of ceramics and sintering of ultra-high-melting-point metals (W, Ta, Mo).

Applications (samples)

- High-crystallization processing of carbon materials (e.g., electrode materials, C/C composites)

- Firing of ceramics undergoing compositional changes at high temperatures (e.g., Si₃N₄, B₄C)

- Sintering and melting of ultra-high-melting-point metals (W, Ta, Mo)

- High-temperature evaluation tests under inert atmosphere for research purposes

- Performance evaluation of oxidation-resistant and heat-resistant materials

Specifications (excerpt)

| Heating Zone | Ø200 mm × 130 mm (H)※ |

| Maximum Temperature | Normal use: 2,800 °C, Max: 3,000 °C |

| Atmosphere | Argon, Nitrogen (usable up to 2,400 °C) |

| Heater | Graphite cylindrical heater |

| Insulation | Molded graphite insulation |

| Required Utilities | 66 kVA power, cooling water, process gas |

Our carbon furnace features a relatively compact heating zone, making it ideal for small-sample evaluations and research under ultra-high-temperature and inert atmosphere conditions. It is particularly recommended for customers with the following needs:

- Test firing during the materials development stage

- Evaluation of ultra-high-melting-point metals and heat-resistant ceramics

- High-crystallization and performance assessment of expensive samples

- Efficiently reproducing conditions that would be excessive in large furnaces using a compact system

Keywords

Ultra-high temperature (2,800–3,000 °C), high crystallization, graphite construction, low-oxygen atmosphere, inert gas atmosphere (Ar, N₂), sintering of ultra-high-melting-point metals (W, Ta, Mo), firing of ceramics (Si₃N₄, B₄C), oxidation-preventive heating, research and development applications

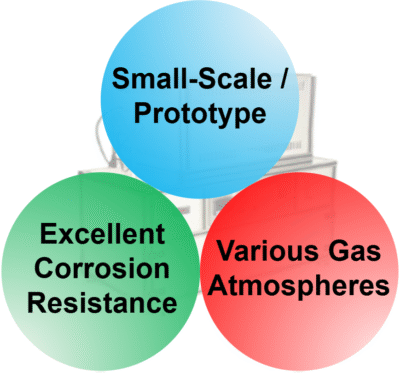

Multi-Atmosphere Furnace

What is a Multi-Atmosphere Furnace?

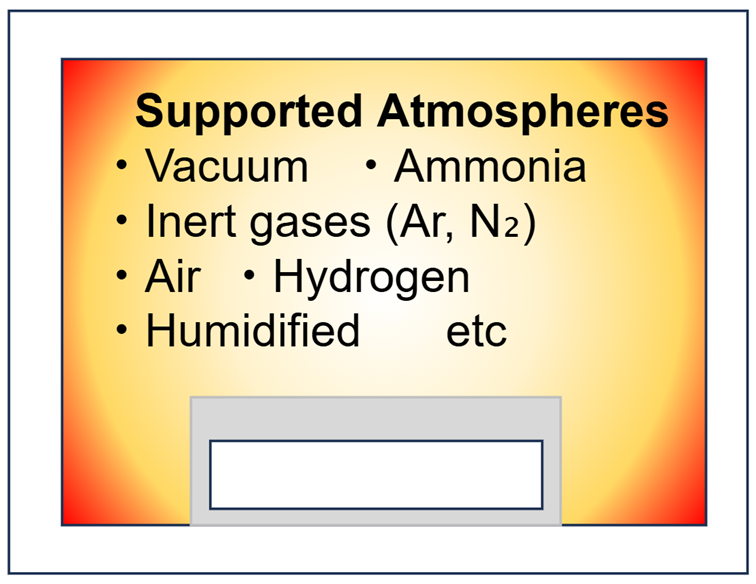

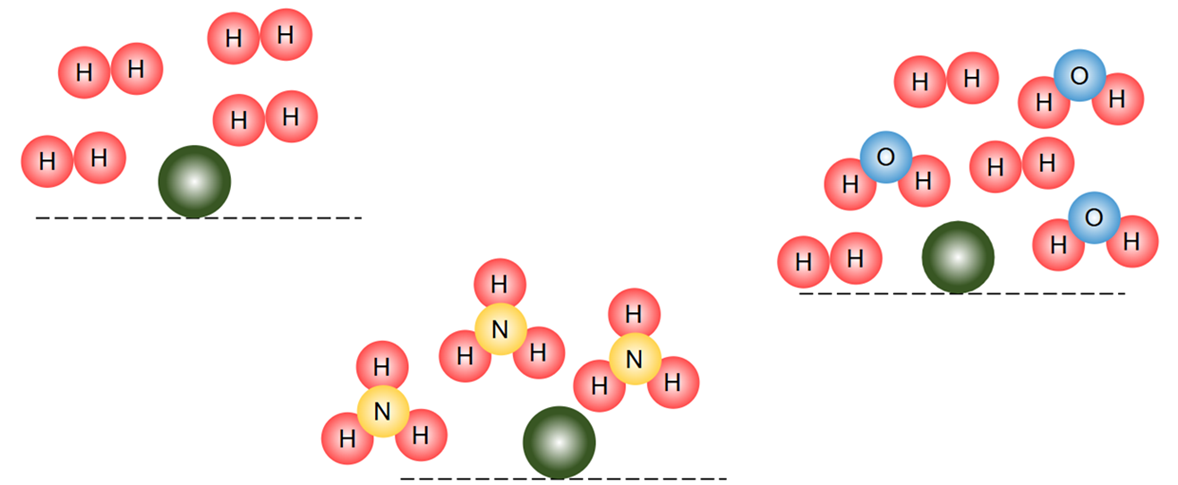

A Multi-Atmosphere Furnace is a versatile system capable of heating not only under vacuum and inert atmospheres but also with gases such as NH₃, H₂, and O₂, allowing operation with a variety of atmosphere. In addition, by humidifying the gas, firing in humid atmospheres is also possible, enabling a wide range of reaction conditions. It is highly effective in research and production settings that require complex atmosphere control, such as reduction, oxidation, nitridation, and humid treatment.

Principle (highlights)

- Atmosphere Switching: A highly sealed furnace body and precise gas‑inlet system allows switching to different gases during processing.

- Humidification Mechanism: Incoming gases pass through a humidification unit (water bubbler) to add water vapor.

- Safety Assurance: When using flammable gases (H₂, NH₃), an optional abatement system ensures safe processing.

Features (highlights)

- Supports vacuum, inert atmospheres (N₂, Ar), oxidizing atmospheres (O₂), and reducing atmospheres (H₂, NH₃)

- Special heat treatments possible with a humidification unit (wetter)

- Optional abatement system safely handles flammable gases generated during reactions

- Maximum operating temperature up to 1,700 °C with a heating rate of 10 °C/min.

- Alumina-sheathed heaters and alumina insulation provide both corrosion resistance and stable heating

Applications (samples)

- Reduction firing of metallic materials (H₂ atmosphere)

- Oxidation treatment (O₂ atmosphere)

- Nitridation reactions (NH₃ atmosphere)

- Catalyst pretreatment or hydroxylation in humid atmospheres

- Evaluation of materials that release reactive gases during firing

- Multi-condition comparative testing in research and development

Specifications (excerpt)

| Operating Temperature | 100 °C – 1,700 °C |

| Atmosphere | Various gases such as Air, N₂, Argon, Ammonia, Oxygen |

| Atmosphere | Alumina-sheathed heater |

| Insulation | Molded alumina insulation |

| Sample Stage | Alumina plate |

Our Multi-Atmosphere Furnace features a compact, high-sealed design, making it ideal for comparative experiments in universities, research institutes, and corporate materials development departments where test conditions must be switched quickly. By combining multiple atmosphere gases with a humidification function, it can reproduce complex firing processes under diverse reaction conditions with a single unit

Keywords

Vacuum, inert gas atmosphere (Ar, N₂), reducing atmosphere (H₂, NH₃), oxidizing atmosphere (O₂), humid atmosphere, atmosphere switching, combined heat treatment, materials evaluation, research and development applications, safe gas handling

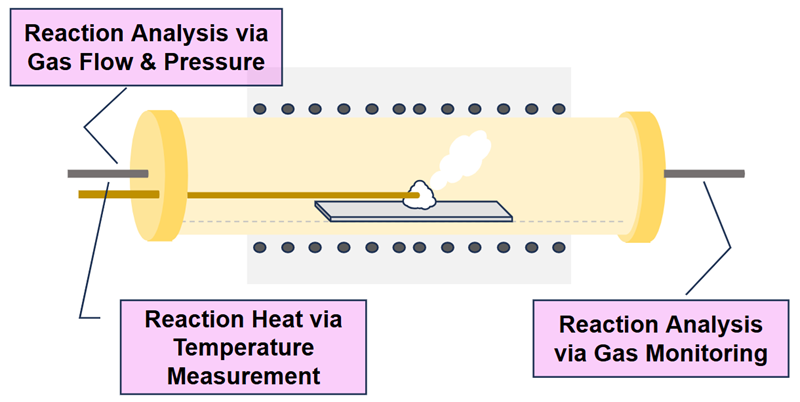

Compact Tube Furnace

What is a Tube Furnace?

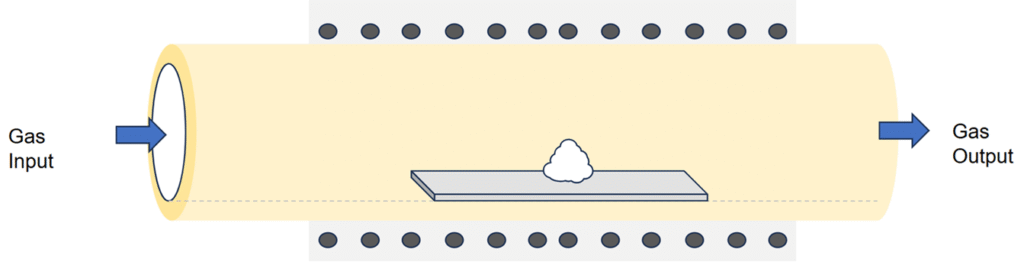

The tube furnace is a compact system in which samples are placed inside a cylindrical heating section (ceramic reaction tube) and heated while various process gases flow through the tube. Measurements of gas flow rate, pressure, and temperature are possible.

Principle (highlights)

- Cylindrical Heating Structure: Provides uniform heating of the entire reaction tube, ensuring stable temperature distribution under gas flow.

- Versatile Atmosphere Compatibility: Capable of supplying various gases, including inert gases, according to experimental conditions.

- Temperature Measurement Function: A thermocouple can be inserted from the inlet side to measure the actual sample temperature, suitable for exothermic reactions and temperature-sensitive processes.

Features (highlights)

- Can heat samples while flowing various gases, offering high flexibility in atmosphere conditions; compact and low-cost, ideal for research and pilot-scale applications

- Allows direct measurement of actual sample temperature via inserted thermocouple

- Reaction tube made of alumina, providing excellent corrosion and heat resistance (rapid temperature changes are not recommended)

Applications (samples)

- Atmosphere testing of small samples (firing evaluation under gas flow)

- Evaluation of material reactivity (simultaneous measurement of flow rate, pressure, and temperature)

- Research on processes involving exothermic reactions or gas generation

- Comparative testing of firing behavior under different gas flow conditions

- Initial evaluation and basic research of new materials

Specifications (excerpt)

| Heating Zone | Ø120 mm × 500 mm L※ |

| Tube Size | Ø70 mm × 1,000 mm L※ |

| Operating Temperature | 1,200℃ |

| Atmosphere | Argon, Nitrogen |

| Heater | Kanthal A1 |

| Required Utilities | 12 kVA, 3‑phase 200 V |

Our tube furnace is compact and equipped with advanced measurement capabilities, specializing in the evaluation of material reactions under gas flow. Optional features allow measurement of sample temperature, gas flow, and pressure, making it ideal for analyzing reaction mechanisms and optimizing test conditions for new materials.

Keywords

Tube furnace, atmosphere testing, compact heating furnace, flow measurement, pressure measurement, sample temperature measurement, inert gas, materials evaluation, reaction behavior analysis, research and development applications

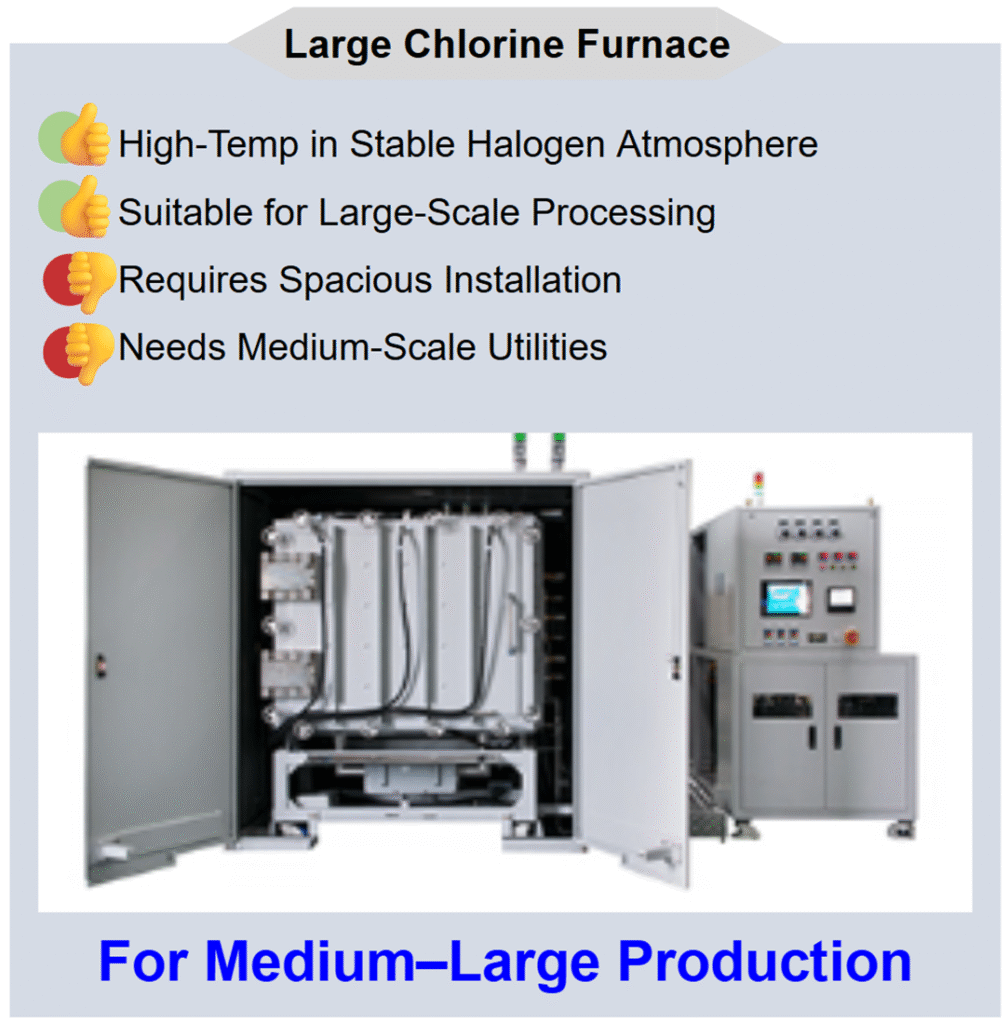

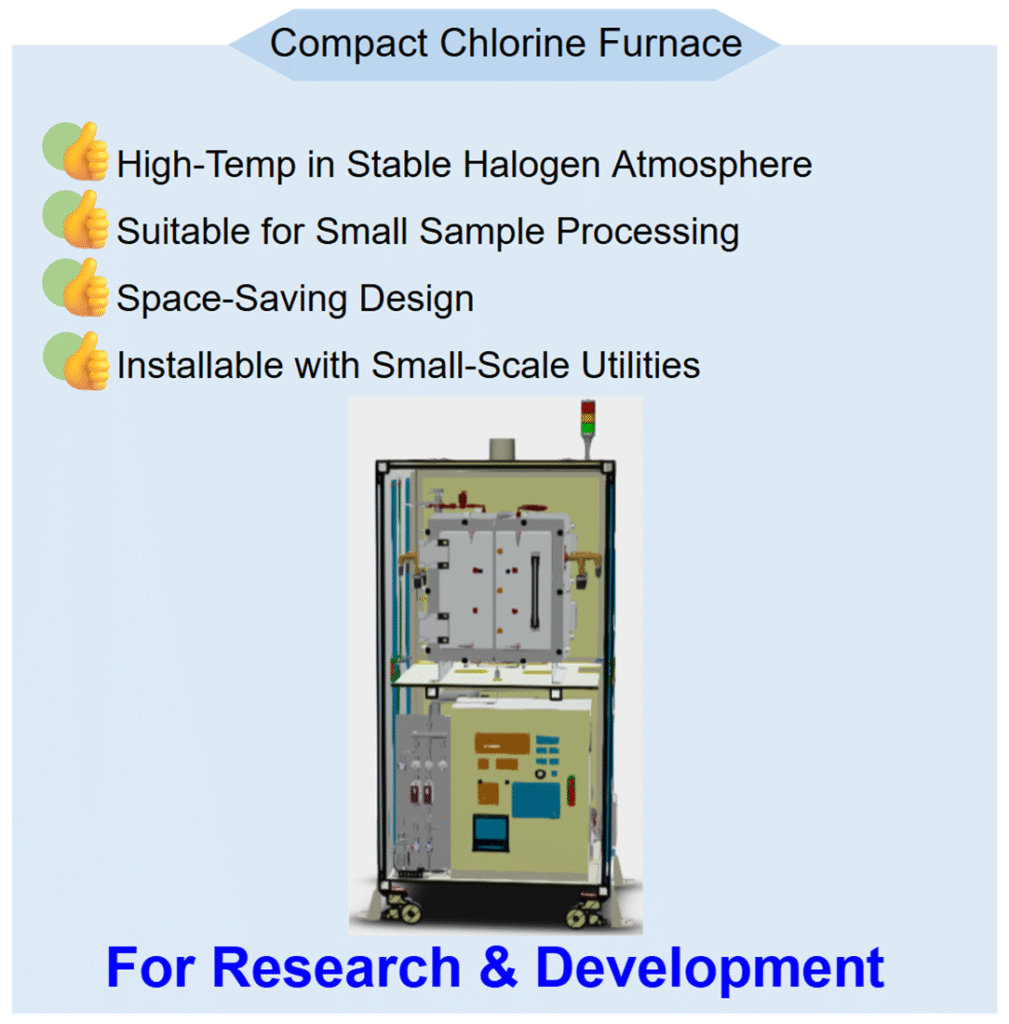

Compact Chlorine Furnace

Background (excerpt)

In recent years, as semiconductor devices become more miniaturized and batteries achieve higher performance, the quality requirements for the powder raw materials used have advanced rapidly. In particular, metal contamination (conductive foreign elements such as Fe, Cu, Ni) originating from raw materials or manufacturing processes can lead to serious defects, necessitating strict control at the ppm-ppb level.

Conventional Methods (excerpt)

- Acid dissolution (e.g., HCl, H₂SO₄)

- Can achieve uniform removal, but generates large amounts of wastewater; not suitable for water-sensitive products

- Removal using powerful electromagnetic separators

- Cannot capture very fine metals (below several tens of μm) or non‑magnetic metals

Principle (term normalization)

Chlorination–volatilization method

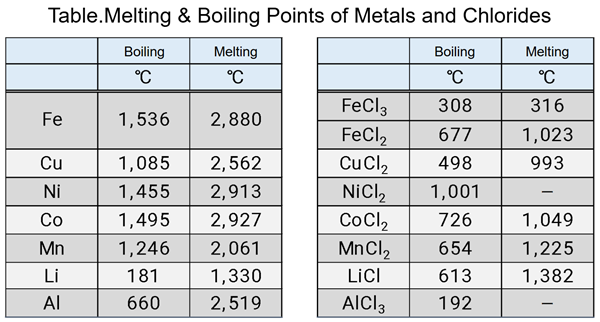

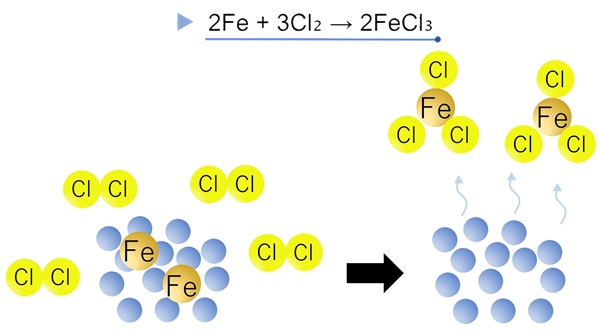

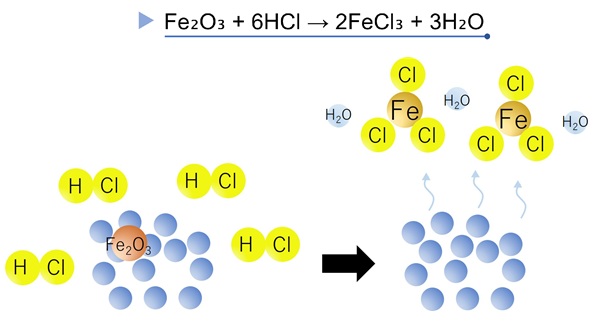

The chlorination volatilization method is a process in which inorganic materials, such as metal oxides or ores, react with chlorine gas (Cl₂) or hydrogen chloride (HCl) to convert them into volatile metal chlorides, which can then be separated and purified.

Features

- Enables selective metal separation by utilizing differences in volatility

- Dry process, generating less wastewater compared to wet methods

Reaction Concept

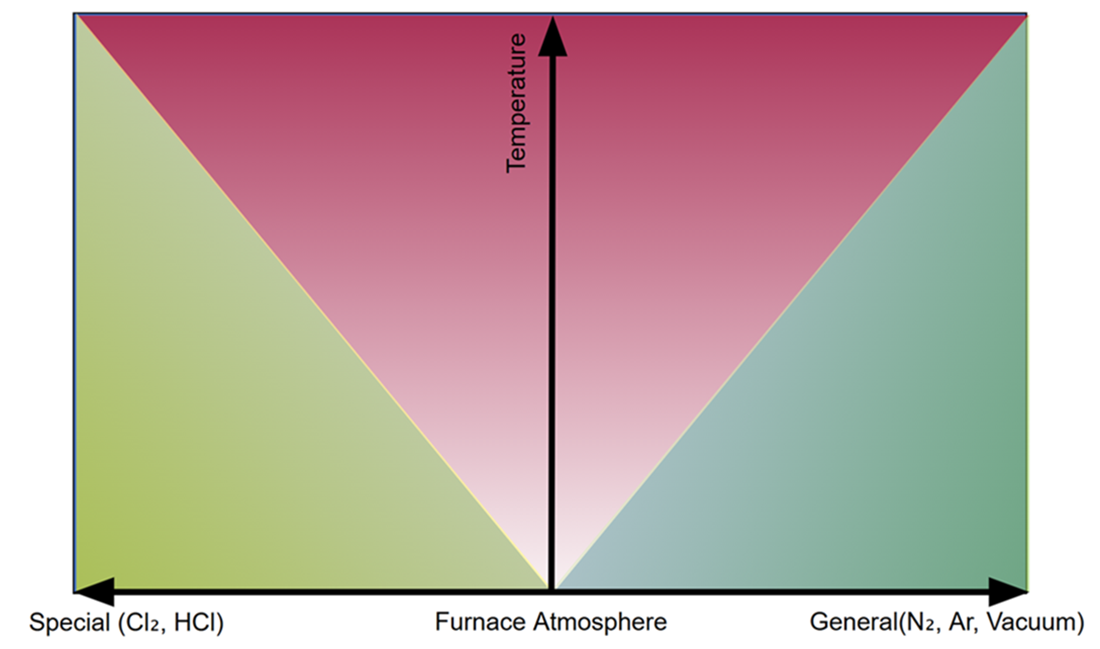

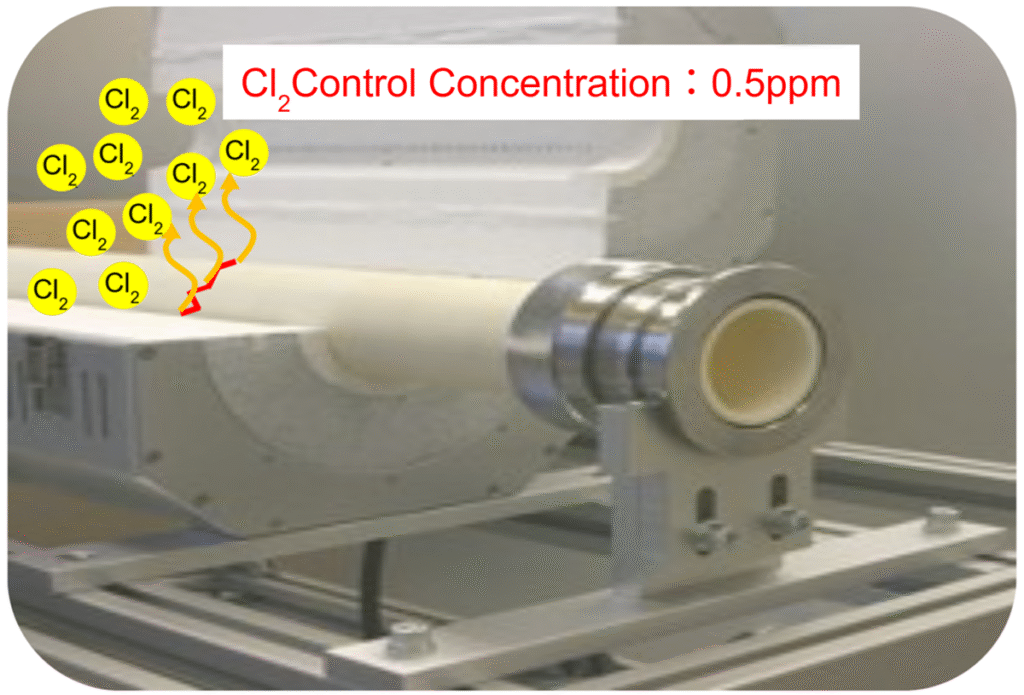

Current Status of Furnaces Compatible with Halogen Gas Atmospheres

- Introducing Cl₂ or HCl at high temperatures is challenging, as they can corrode the equipment

- Limited to evaluation using small electric furnaces with corrosion-resistant materials, such as alumina tube furnaces

- In tube furnaces, the slightly pressurized atmosphere poses a risk of serious accidents in case of leakage

Features (excerpt)

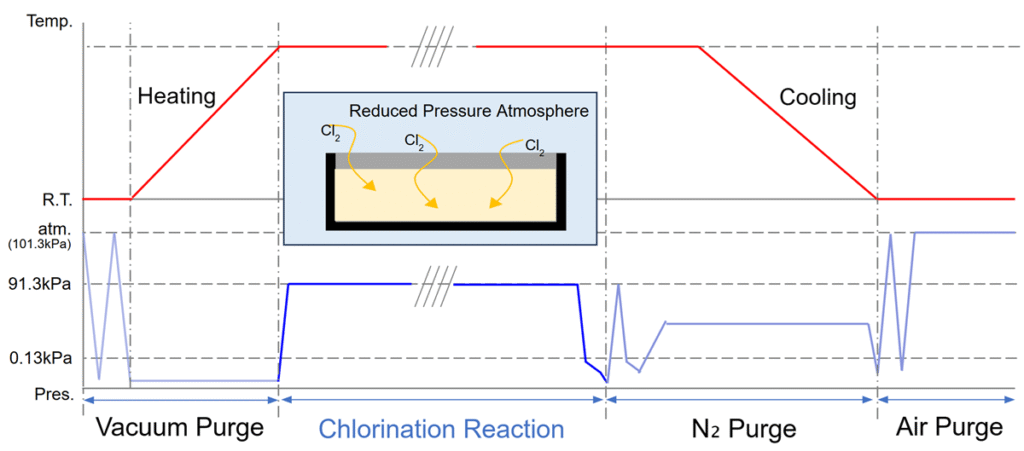

- Supports halogen gases such as Cl₂ and HCl using Thermonik’s proprietary technology (CE, SEMI, UL certified)

- Uniform heating enabled by the use of shelf-type heaters

Since the reaction is always carried out under a reduced‑pressure atmosphere:

- Cl₂ gas diffuses throughout the sample, enabling highly efficient reactions

- The boiling points of generated chlorides are lowered, allowing processing at lower temperatures

- Reduces the risk of Cl₂ or HCl gas leakage

Example of Operation

Previous Applications

- Purification of carbon nanotubes (CNTs): Removal of metal catalysts (Fe, Co, Ni, etc.) used during CNT synthesis

- Cleaning of susceptor (GaN): Removal of GaN accumulated on susceptor fixtures

- Reduction of phase transition temperature: Control of crystal phase transitions in ceramics

Suitable for metal removal processes or reaction-controlled furnaces where water-sensitive products or processes generating large amounts of wastewater must be avoided.

Further Applications

- Selective separation/recovery of rare metals

- Products requiring ultra-high purity

- Development of new materials

- Surface modification of materials (hydrophobic → hydrophilic)

- Corrosion evaluation of superalloys

Specifications (key fields)

| Furnace Dimensions (W×D×H) | 200 mm × 200 mm × 200 mm |

| External Dimensions (W×D×H) | 1,000 mm × 1,000 mm × 2,100 mm |

| Gas Atmosphere | Cl₂, HCl, N₂, Ar, H₂ |

| Temperature | Up to 1,400℃ |

| Vacuum Level | Several Pa |

| Required Utilities | Cooling water, electricity, N₂ or Ar, process gas |

| Operation Mode | Batch |

※Specifications are for the current development model and are subject to change without notice.

No complicated preparation is required on the user side. With the utilities connected, it can be used immediately as an all-in-one design.